Shisha charcoal making machine for hookah briquette tablet production

Hookah charcoal press machine/Shisha charcoal briquette machine

Shisha charcoal making machine for hookah briquette tablet production

Hookah charcoal press machine/Shisha charcoal briquette machine

Features at a Glance

The stainless steel shisha charcoal making machine is a high-quality equipment for preparing hookah charcoal, which is used to make strong charcoal briquettes from pre-treated hookah charcoal raw materials through the process of mechanical extrusion and molding.

Its main feature is that it is made of stainless steel material, which has the advantages of corrosion resistance, abrasion resistance, and hygienic and easy cleaning. Shuliy’s charcoal press machine can make shisha briquettes in many shapes.

Overview of shisha charcoal making machine

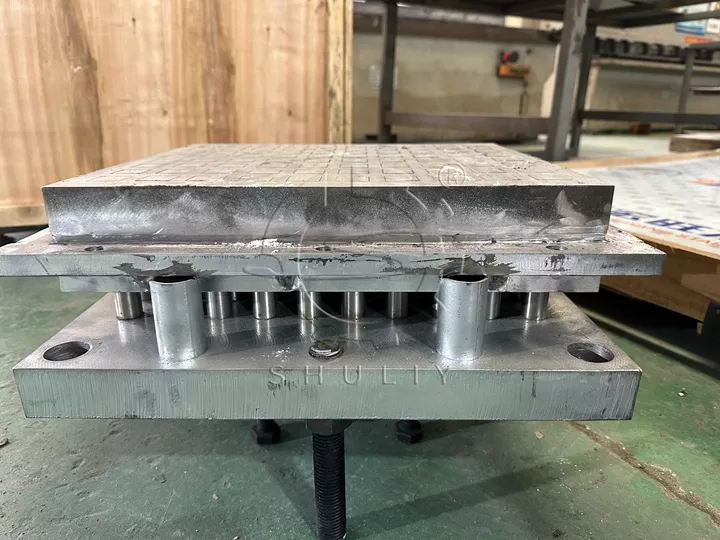

The most important function of a stainless steel shisha charcoal making machine is extrusion. Pressure is applied to press the charcoal powder or mixture into a solid charcoal briquette. It usually includes a pressure mechanism, a gland, and a briquette die.

The density and hardness of the charcoal briquettes can be controlled by adjusting the pressure and time. And we will customize the molds that customers need according to their needs.

Raw materials handled by shisha charcoal making machine

The best and most commonly used raw material for making shisha charcoal briquettes is coconut shell charcoal powder. In addition to this, natural wood is used, such as oak, teak, apple wood, and cherry wood.

Wood charcoal powder usually has a good burning performance and a long charring time. Bamboo charcoal powder mix charcoal powder. All of these raw materials are first charred, which can through a continuous charcoal carbonization furnace, then be processed into powder form in a grinder. The finer the powder, the smoother and better looking the finished product.

What is the application of hookah charcoal?

Hookah charcoal is a tobacco product used in waterpipe smoking. Hookah charcoal first originated in the Middle East, where a long culture and tradition of hookah smoking has developed.

Waterpipe smoking is seen as a way to socialize, have fun, and relax, and people often use waterpipe charcoal in homes, cafes, or social settings. Hookah charcoal can be combined with different tobacco flavors and spices to obtain a variety of flavored hookahs.

Working video of hookah charcoal machine

Finished shisha charcoal briquettes

Various shapes of hookah charcoal briquettes can satisfy most customers’ needs. Here are a few reasons why so many people choose hookah charcoal:

- Good market prospect: Waterpipe charcoal in the Middle East is a local culture and tradition. Many people in the region are using sooty charcoal.

- Environmentally friendly: Some people choose to make shisha charcoal because they are looking for a more environmentally friendly tobacco option. Compared to traditional cigarettes, making hookah charcoal reduces the amount of tobacco used and the production of cigarette butts, thus having a smaller impact on the environment.

- Economic factors: For commercial producers, making hookah charcoal can reduce costs and increase profits. Making your own charcoal briquettes allows you to control the cost and availability of raw materials, thus improving the economics of production.

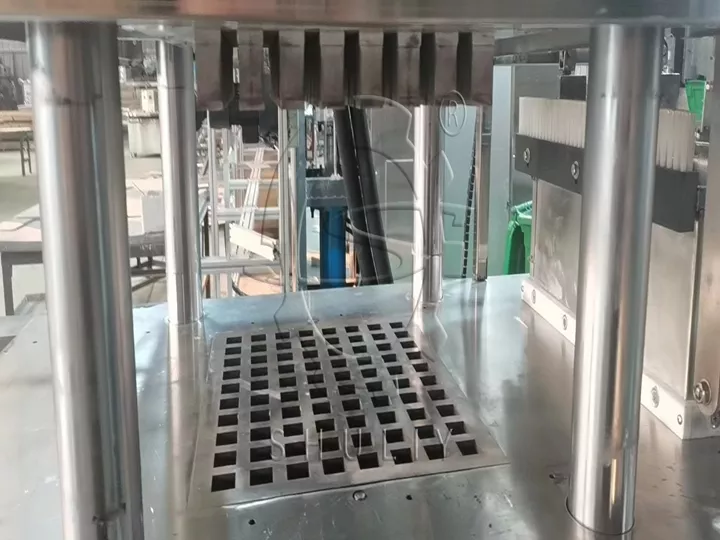

Structure of charcoal briquette press machine

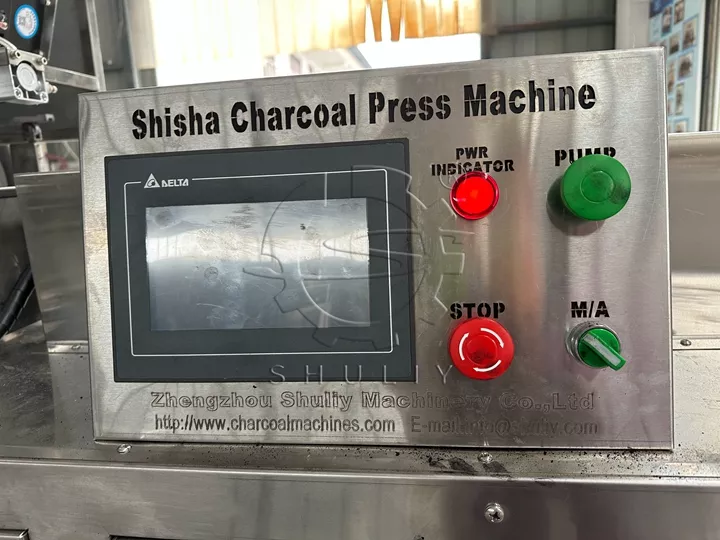

Shisha charcoal making machine mainly consists of a machine frame, pressure system (which is the core part of the machine usually consists of a pressure mechanism, press cover, and briquette mold), heating system, control panel, discharging port, and so on.

The stainless steel shisha charcoal making machine is usually equipped with a control system, which can adjust parameters such as pressure, temperature, and pressing time to meet different needs and charcoal quality requirements.

Process of making shisha charcoal briquettes

- Use the charcoal furnace to carbonize the raw material first.

- Use a grinder to grind the carbonized charcoal. After grinding, the charcoal powder is more delicate.

- Mixing and stirring: Mix the charcoal powder and binder thoroughly to ensure even distribution. We recommend customers use a professional binder, which is helpful to reduce the ash.

- Pressing and molding: Put the mixture into the shisha charcoal making machine for pressing.

- Drying and Packing: Dry the molded charcoal briquettes in a batch drying machine to the right dryness and humidity. Use the hookah charcoal packing machine to pack the finished products for sale.

Working principle of shisha charcoal making machine

- Prepare charcoal powder: First of all, you need to prepare charcoal powder or charcoal powder mixture as raw material.

- Add charcoal powder: Put the prepared charcoal powder into the feeding hopper of the shisha charcoal-making machine.

- Pressing and molding: Start the shisha charcoal making machine. The hopper of the hookah charcoal machine opens to put the charcoal powder into the mold. The pressure mechanism applies pressure to press the charcoal powder into solid charcoal briquettes.

- Discharge charcoal briquettes: Once the charcoal briquettes are formed, the stainless steel hookah charcoal machine will push out the charcoal briquettes. It is convenient for users to collect the charcoal briquettes.

Detailed pictures of different molds

Cubic shisha charcoal press machine technical parameters

Different models and manufacturers of stainless steel shisha charcoal making machines may have different technical parameters. When choosing the right machine, you need to consider the below technical parameters and other possible influencing factors according to your own needs, production scale, and actual situation.

| Model | Pressure | Voltage | Power | Weight | Dimension |

| SL-SS | 80tons, 100tons | 380V | 13kw | 1000kg | 2500mm*750mm*2300mm |

Why choose the Shuliy shisha charcoal making machine?

- Quality and reliability: We are a well-known manufacturer. Shuliy’s products are carefully designed and manufactured. Choosing Shuliy’s shisha charcoal making machine can ensure the stability and durability of the equipment.

- Customizability: We will provide customers with customized options to meet different customers’ needs and requirements. For example, the mold of the hookah charcoal, the power of the machine, the operating system of the machine, and so on.

- Reasonable price: The price of our shisha charcoal making machine is proportional to the quality of the machine. It will not be overpriced. Customers can buy with confidence.

- High-quality after-sales service: Shuliy will have high-quality after-sales service, professional technical support, and maintenance service. We expect to establish a long-term relationship with our customers and make sure that they get timely support and solve problems in the process of using the equipment.

Meanwhile, our company also sells other types of hookah charcoal machines, such as rotary shisha charcoal machines and hydraulic hookah charcoal press machines. For price and detailed information, please feel free to contact us!

Hot Product

Briquette charcoal dryer for honeycomb shisha coal production

Briquette charcoal dryer refers to the evaporation of…

Charcoal grinder machine for briquette molding plant

Charcoal grinder machine has the functions of crushing,…

Wood pallet press machine in pallets production making line

The wood pallet press machine is our featured…

Honeycomb coal machine for briquette forming production line

A coal briquette press machine is used to…

Wood shaving machine for animal bedding

The wood shaving machine is mechanical equipment used…

Wood chipper machine for sawdust-making plant

Wood chipper is a highly efficient wood processing…

Hammer mill crusher in sawdust-making production line

Shuliy hammer mill crusher is a kind of…

Feed pellet mill machine for farming use

The feed pellet mill machine is a kind…

Automatic saw mill machine for wood recycling plant

An automatic saw mill machine is a mechanical…