Continuous carbonization furnace for rice husk charcoal making

Rice husk charcoal machine/Charcoal burning machine

Continuous carbonization furnace for rice husk charcoal making

Rice husk charcoal machine/Charcoal burning machine

Features at a Glance

Continuous charcoal carbonization furnace is an ideal equipment for dry distillation, oxygen-free carbonization, and high carbonization rate of carbonized biomass materials such as wood chips, rice husk, peanut shells, plant straw, and so on under high-temperature conditions in the furnace.

Generally, the diameter of carbonized material is below 50mm. This is the difference between continuous carbonization furnace and horizontal carbonization furnace. And can produce up to 800-1000kg/h.

Continuous charcoal carbonization furnace overview

Continuous charcoal carbonization furnace is a kind of equipment specially used for the carbonization of fine granular materials. It can convert raw materials into charcoal in a continuous process. The material after carbonization is usually in granular form as well. People will further pulverize the charcoal particles into charcoal powder according to their needs.

Compared with the traditional batch charcoal furnace, the continuous charcoal furnace is able to realize continuous operation. Therefore, the continuous charcoal-burning machine is more efficient in some mass production scenarios.

Charcoal burning machine raw materials

Continuous charcoal carbonization furnace can carbonize a wide range of materials. For example, wood chips, rice husk, peanut shells, plants, bark, straw, organic matter, hemp stalks, walnut shells, coconut shells, palm shells, and other carbonaceous wood materials.

Finished product of rice husk charcoal machine

The biomass char produced by the continuous charcoal carbonization furnace has a wide range of uses in many fields such as energy supply, industrial applications, agriculture, and environmental protection.

This kind of charcoal has a deep color, high calorific value, and stable combustion, which has a good application prospect. Biomass char for different applications may require certain processing and treatment to meet specific requirements.

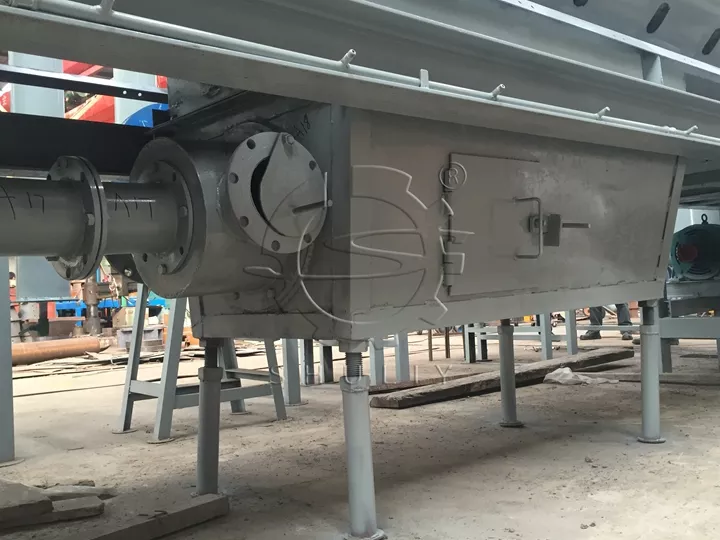

Structure of continuous carbonization furnace

Continuous carbonization furnace includes carbonized, gasifiers, soot processors, combustible gas purifiers, combustible gas condensers, induced draft fans, and other components. It is not easy to be used for carbonization of larger materials, and the use of advanced carbonization technology is that the whole process does not produce harmful gases and does not pollute the environment.

Working principle of continuous carbonization furnace

Continuous charcoal carbonization furnace is to burn the materials through the gasifier first to produce flue gas. Then it goes through the flue gas purification system to filter out the wood vinegar, wood tar, smoke, and so on. These flue gases will be transmitted into the carbonized for burning to reach a certain temperature, and then add materials to the continuous carbonization furnace. Through pipeline transmission, the material will be burned in the carbonized.

- LPG ignition machine, the machine needs to be preheated, it takes about 1 hour, it needs 20-30kg of LPG to ignite once, the whole process only needs to ignite LPG once.

- The preheating temperature reaches 280°-330°. When the preheating is completed, put in the raw material (when the raw material is a coconut shell, the furnace temperature is 330 degrees when the material, the raw material is palm shells and rice husk, wood chips, and other lighter raw materials, the furnace temperature reaches 280 ° when the material.)

- Ignite the combustion chamber. Carbonization after 10-20 minutes, feel and observe the combustion pool when there is hot gas production, light the gas, combustion chamber combustion, close the fire head, and no longer use LPG.

- It takes 20 minutes to carbonize one round.

- Discharge is a cooling process with, condensing tube, double layer, the inner out of the carbonization of raw materials, and external water for cooling.

Technical parameters for rotary charcoal carbonization furnace

The technical parameters of continuous charcoal carbonization furnace may vary according to different models, manufacturers, and carbonization process. The following are some common technical parameters of our best-selling continuous carbonization furnace:

| Type | LT-800 | LT-1000 | LT-1200 |

| Diameter(mm) | 800 | 1000 | 1200 |

| Capacity(kg/h) | 400-600 | 800-1000 | 1200-1500 |

| Main Power(kw) | 18.5 | 18.5 | 20 |

| Carbonization Temperature(℃) | 500-800 | 500-800 | 500-800 |

| Fan Power(kw) | 5.5 | 5.5 | 5.5 |

Please note that when choosing a suitable continuous carbonization furnace, you need to consider the above parameters and other possible influencing factors according to your own needs and actual situation.

Continuous charcoal carbonization furnace benefits

- Compact structure, Economic Space Occupation, high produce efficiency

- Heating up evenly, upgrades heat treatment quality

- Having a variety of pipe fittings, spare can realize all kinds of chemical processing

- Furnace tilting and discharging are convenient.

Delivery of continuous charcoal carbonization furnace

Continuous charcoal carbonization furnace has the advantage of high efficiency and high output. Therefore, most of the users choose it for biochar production in order to save production time. We have shipped this machine many times. Below are some pictures of the sites sent to Ghana and the UK.

FAQs about charcoal furnace machine

1. Is there any requirement for moisture in raw materials?

The moisture of raw material should be less than 20%, if the moisture is high, it needs to be dried in advance with drying equipment.

2. What is the feeding size of the material?

The feeding size of the material is 10 centimeters or less.

3. How much space is needed for one piece of wood charcoal-making machine?

A device probably needs 250-300 square meters of space, the width can not be less than 10 meters, the length of 22 meters.

4. How many people do I need to operate a continuous carbonization furnace?

One continuous charcoal carbonization furnace can be operated by 3 workers.

Hot Product

Wood shaving machine for animal bedding

The wood shaving machine is mechanical equipment used…

Wood pallet press machine in pallets production making line

The wood pallet press machine is our featured…

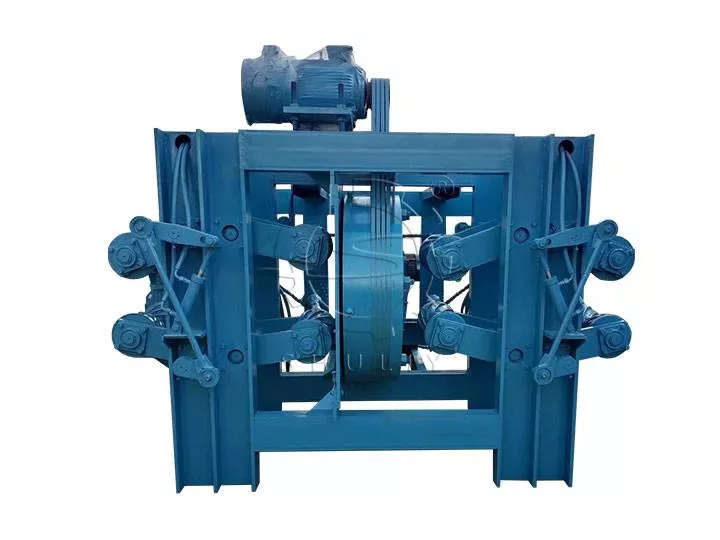

Charcoal Ball Press Machine For BBQ Industry

Charcoal ball press machine is efficient and convenient…

Charcoal grinder machine for briquette molding plant

Charcoal grinder machine has the functions of crushing,…

Wood debarker machine for wood chip production

The wood debarker is a machine that specializes…

Comprehensive crusher in charcoal processing plant

The comprehensive crusher is a multi-functional processing equipment,…

Shisha charcoal making machine for hookah briquette tablet production

The shisha charcoal making machine is also a…

Charcoal briquette mesh belt dryer for continuous drying plant

Charcoal briquette mesh belt dryer is a continuous…

Hookah charcoal packing machine for shisha briquette bagging plant

Hookah charcoal packing machine is a special equipment…