Successful export of MBJ180 charcoal extruder machine to Kenya

Our company is very pleased to announce that at the end of last month, we successfully sent an MBJ180 charcoal extruder machine to a regular customer from Kenya. Now the customer has put it into use and the feedback is good.

Background information on the customer

The customer had purchased our charcoal ball press machine before, and because of the high quality of the machine, the customer increased his confidence in our machine and contacted our company, saying that he needed a small-capacity charcoal extruder machine.

So this time, he wanted to start the coal bar production business and contacted our company in early July, saying that he needed a small and medium-sized charcoal extruder machine. Through detailed communication, the customer accepted our MBJ180 model, which is also in line with his expectation.

Increasing demand for charcoal briquette machines in the market

In recent years, the demand for coal bar machines in the market is gradually increasing, which is mainly attributed to the energy transition, rising environmental awareness, and the growing importance of renewable energy sources. The following are some of the key factors that have led to the increase in market demand for coal bar machines:

- Energy Security and Stability of Supply: Biomass energy sources such as wood chips, straw, etc. as renewable energy sources can help increase the diversity and stability of the energy supply and reduce dependence on imported coal, thereby enhancing energy security. It not only reduces carbon emissions but also helps reduce the demand for finite fossil fuels.

- Demand from emerging markets: A number of emerging markets and developing countries are seeking sustainable development solutions in the energy sector, and coal bar machines provide a cost-effective way of converting renewable resources into fuels to meet local energy needs.

Why choose Shuliy charcoal extruder machine

The performance of the Shuliy charcoal briquette machine involves many aspects, including production capacity, pressing efficiency, and coal stick quality. The following are some common machine performance indicators of charcoal extruder machines:

- Production capacity: Production capacity refers to the number of coal rods that a coal rod machine can produce per hour. It is usually affected by the design and size of the machine. The production capacity of different models of coal briquette machines may vary, ranging from a few hundred to a few thousand briquettes.

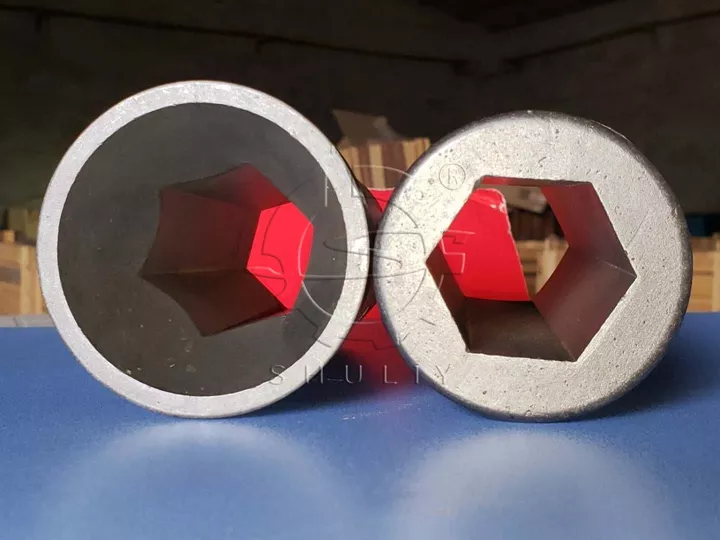

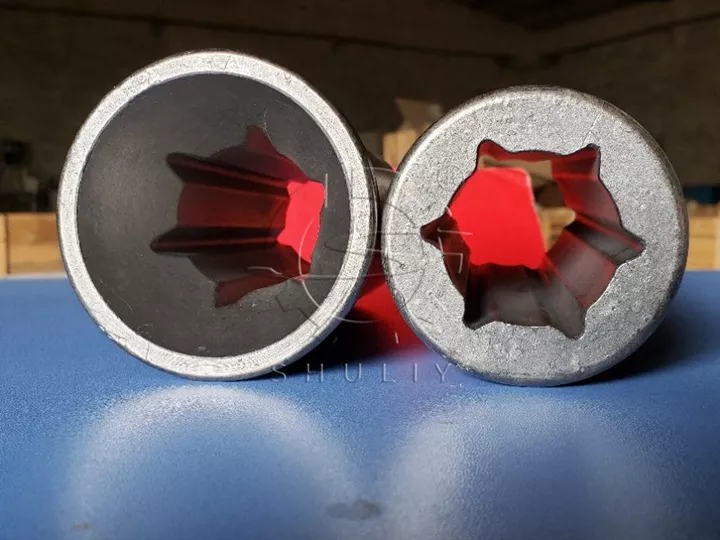

- Size and shape of coal rods: Coal rod machines usually allow the size and shape of the rods to be adjusted to suit different applications. A well-built machine will produce consistent and to-specification briquettes.

- Density of Coal Bars: Coal bar density is defined as the ratio of weight to volume of a coal bar. A higher density of briquettes means that the calorific value of the fuel in the briquettes is higher and more energy can be supplied.

- Automation Degree: Some modern coal briquette machines have a high degree of automation, which can realize automatic feeding, pressing, discharging, and other functions, reduce manual intervention, and improve production efficiency.

Feedback from the Kenya customer

Our customers are very satisfied with the performance and durability of the charcoal extruder machine. The high efficiency of this machine enables them to meet market demand and expand business operations. He also pointed out that the machine has significantly reduced manual labor, increased productivity, greatly reduced pollution, and significantly improved air quality.

Overall, the advantages of charcoal extruder machines lie in their environmental friendliness, sustainability, economy, and role in energy transition. It helps to promote the development of clean energy, reduce carbon emissions and realize the goal of sustainable development.