Successful delivery of 1 set of pallet block press machines to Indonesia

We are very pleased to announce the successful shipment of one set of our pallet block press machines to Indonesia recently. In early July, the customer searched our product website and became interested in our products, and contacted us, indicating that he needed a machine for processing wood mat blocks.

Through detailed communication, we built the machine according to the customer’s requirements on parameters and successfully shipped it within the specified time. At present, the customer has received the machines and put them into use, reflecting good.

Increasing market demand for pallet block press machines

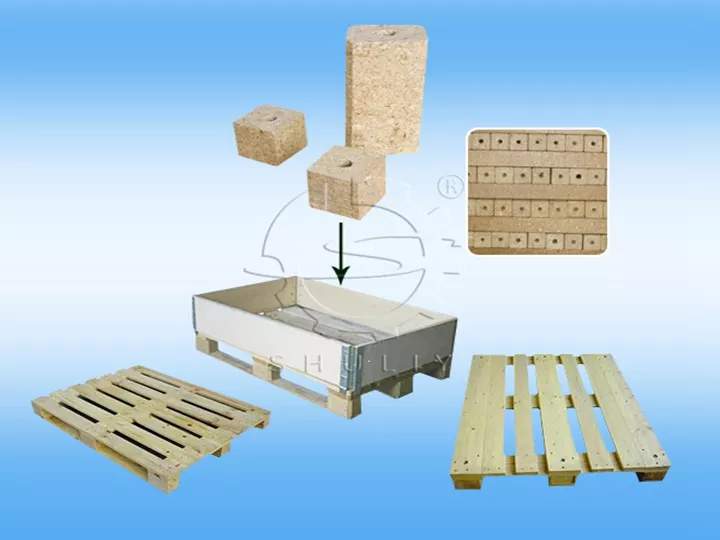

This wood pallet block machine has attracted the attention of our Indonesian partners with its high efficiency and environmentally friendly features. As an innovative production equipment, the wood briquetting machine is able to transform waste wood into high-quality and sustainable wood briquettes, making a positive contribution to environmental protection and resource recycling.

Background of the customer

Wooden pads play an important role in logistics and transportation, and they have a positive impact on the protection, stability, and efficient transportation of goods.

Our Indonesian customer is none other than the owner of a logistics company. He purchased the machine in order to secure the goods during their shipment so that they would not be bumped and avoid losses.

Attractive features of Shuliy pallet block press machine

Wood pallet block press machines play an important role in logistics transportation, which has a positive impact on the protection, stability, and efficient transportation of goods. The following are the roles of wood cushion blocks in logistics transportation:

- Cargo protection: Wooden blocks can be used for cargo support and protection against damage, deformation, or collision during transportation. They provide additional support and stabilization at the bottom and sides of the pallet, reducing the impact on the goods due to shock or vibration.

- Stabilizing Stacking: Wooden blocks can be used to stabilize goods during stacking and prevent them from collapsing or collapsing during stacking. They can provide balanced support in the stacking, making the stack of goods stronger and more stable.

- Easy handling: Wooden pads enable forklifts, handling equipment, etc. to be easily inserted into the bottom of the pallet, facilitating the handling and loading and unloading of goods. They provide a stable handling platform and help improve handling efficiency.

- Saving space: Wooden blocks allow goods to be stacked at regular intervals, which allows better use of storage and transportation space and improves the efficiency of goods transportation.

Overall, wood pallet block press machines play a role in stabilizing, protecting, supporting, and improving efficiency in logistics and transportation. They help keep goods intact during transportation and reduce the risk of damage, while also facilitating smooth logistics operations.

Feedback from Indonesian Customers

Our customers are very satisfied with the performance and durability of this machine. The high efficiency of the machine enables them to meet the market demand and expand their business operations. He also pointed out that more businessmen are willing to cooperate with his logistics company, which drives the development and promotion of the company.