Presswood pallet production line for wood recycling plant

The presswood pallet production line is widely put into use by wood processing plants. Manufacturing wooden pallets is mainly used for stacking, loading, and transporting goods. The use of wooden pallets facilitates mechanized loading and unloading and improves handling efficiency.

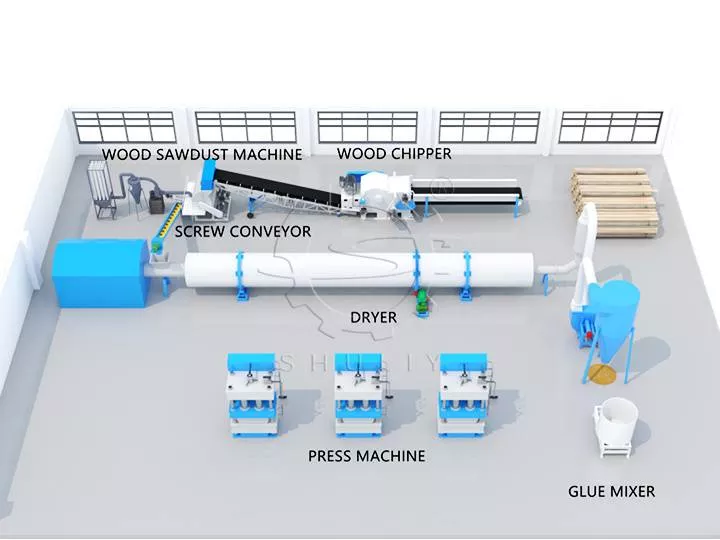

The pressed wood pallet production line takes logs, waste wood, etc. as raw materials, and the workflow of the whole line is highly automated and continuous, through the coordination and cooperation of various workstations, after a series of operations, it realizes the whole production process from the preparation of raw materials to the making of finished products, which is finally processed into wood pallets with various uses.

Raw materials of presswood pallet production line

The presswood pallet production line is mainly used to produce presswood pallets by compression molding with sawdust, shavings, wood chips, straw, coconut fiber (coconut palm), and other fibers processed from logs as raw materials.

Workflow of compressed wood pallet making line

If you want to invest in a high-yield wood recycling program or a pallet program, Shuliy is your one-stop solution. A complete production line for processing wooden pallets should include the following range of wood processing equipment: wood chipping machine → hammer mill crusher→ screw conveyor → dryer machine→ glue mixer → wood pallet press machine.

In order to get the wood pallets that meet the needs of the majority of users, we are equipped with the appropriate model of each piece of equipment in the entire production line, saving customers the trouble of choosing the model of the machine.

Drum wood chipper: Crush wood logs into wood chips

The drum-type wood chipping machine installs knife rollers and blades inside a cylindrical rotating drum, and the raw materials come into contact with the blades inside the drum to slice fibrous and lumpy biomass raw materials such as wood, bamboo, straw, etc. into fine particles or thin slices.

Model: SL-216

Input size: 230*500mm

Knife roller speed: 590r/min

Size of finished product: 50*50mm

Power of Main Motor: 55kw

Weight: 4300kg

Capacity: 5t/h

Hammer mill crusher: Crush wood chips into sawdust

Hammer mills are usually suitable for processing various types and sizes of wood waste, branches, boards, chips, etc. They use hammer blades to chop and pulverize wood to form sawdust.

Model: SL-500

Input size: 230*500mm

Hammer Number: 40pcs

Size of the finished product: 10mm

Power of Main Motor: 22kw

Diameter of Dust remover: 800mm

Capacity: 500kg/h

Rotary dryer machine: Reduce the moisture of sawdust

The moisture content of wood sawdust used for the production of wooden pallets should be less than 10%, so a dryer is needed to dry and reduce the moisture content of the sawdust.

Model: SL-D800

Weight: 1800kg

Thickness: 8mm

Diameter: 800mm(D)

Power: 3kw

Fan power: 5.5kw

Capacity: 500-600kg/h

Glue mixer: Mix sawdust with glue

In order to increase the density of the finished product, the raw material needs to be mixed with glue, which is usually urea-formaldehyde resin glue. The purpose of this is to make the finished product stronger and have more load-bearing capacity.

Model: SL-900

Dimension: 1.5*1*1.4m

Diameter: 900mm

Weight: About 300kg

Power: 7.5kw

Glue: Urea-formaldehyde resin glue

Pallet press machine: Produce wood pallets

At this point, the raw materials to be processed into wooden pallets have been completely ready, now the raw materials are in the machine, wood pallet molding machine through the hot pressure on the pallet, high temperature also has a sterilization effect.

Model: SL-1000

Dimension: 1.9*1.3*4m

Pressure: 1000tons

Weight: 21000kg

Power: 15kw

Capacity: Produce one pallet need 4-5 minutes

Advantages of presswood pallet production line

- High quality of finished pallets: Compression-molded wood pallets are of high quality with smooth surfaces, high load-bearing capacity, good waterproof performance, and fumigation free.

- Fully automated: The presswood pallet production line offers a fully automated production solution. Only one or two staff members are sufficient to handle the routine operations of the entire line.

- Wide range of applications: Various shapes/sizes of pallets can be produced by simply changing the compression molding method.

- Cost saving: The line can significantly reduce raw material costs by utilizing fibers such as waste wood, wood sawdust, shavings, wood chips, straw, and coconut fiber (coir fiber).

- Environmental protection and energy saving: The heat source of the production line can be supplied in various ways. Energy consumption is low. It is ideal for recycling wood waste in an environmentally friendly way.

Presswood pallet production line finished product

These are some of the common types of finished wood pallets, and there are actually many other shapes, sizes, and designs that can be custom-fabricated to suit specific goods and needs. Presswood pallet production line plays a key role as an important piece of logistics equipment in a variety of industries, facilitating and supporting the transportation and storage of goods.