Wood chipper machine for sawdust-making plant

Wood chips making machine/Wood chipping machine

Wood chipper machine for sawdust-making plant

Wood chips making machine/Wood chipping machine

Features at a Glance

Wood chipper is a highly efficient wood processing equipment that finely cuts raw materials such as wood, bamboo, straw, and other materials into fine particles or thin slices by rotating knives. It works in a simple but effective way, and the cutting parameters can be adjusted as needed to produce finished products suitable for a wide range of fields such as biomass energy, wood products, and furniture manufacturing.

The wood chipper machine is usually not used alone, mostly used in production lines. The back end can add a wood hammer mill crusher for further crushing into sawdust, and then it can be used for charcoal making and other operations.

Wood chipping machine plays an important role in resource utilization and environmental protection, promoting the sustainable development of the industry. Whether it is to improve productivity or reduce costs, the wood chips-making machine is an indispensable key tool in modern industry. Shuliy Processing has two styles of this machine, the disk wood-chipping machine, and the drum wood chips making machine.

Working Principle of the two machines

Disk wood chipper: uses a flat rotating blade disk with blades mounted on it, the raw material is in contact with the blade disk and the blades cut the wood into thin slices or particles.

Drum wood chipper: uses a cylindrical rotating drum with blades or a combination of blades mounted inside the drum. The wood comes in contact with the blades inside the drum, and the wood is planed into thin slices or particles through the cutting of the blades.

Disc wood chips making machine

The disc-type wood chipping machine is a processing machine used to cut fibrous and lumpy biomass raw materials such as wood, bamboo, straw, etc. into thin slices or pellets. It can be made into different styles or shapes according to the customer’s requirements, as shown below.

Disc wood chipper main accessories

Its working principle is based on a flat rotating disk with blades mounted on it, where the raw material comes into contact with the disk and the blades cut the wood into the desired form by rotating.

Features of disc wood chipping machine

The cutting method of the disk cutter usually produces smoother shavings and is suitable for applications that require a smoother surface, such as furniture manufacturing. Disc wood chips making machine usually has a simple structure, which is easy to operate and maintain. Out of the material, the finished product upward blows out, but the size of the material can not be adjusted and is controlled at about three centimeters, regular and uniform.

Mobile-type disc wood chipper machine

According to the user’s needs, the machine can be customized, for example, we can add wheels at the bottom of the machine, which can facilitate customers to use this machine in different scenarios, greatly saving time and improving work efficiency.

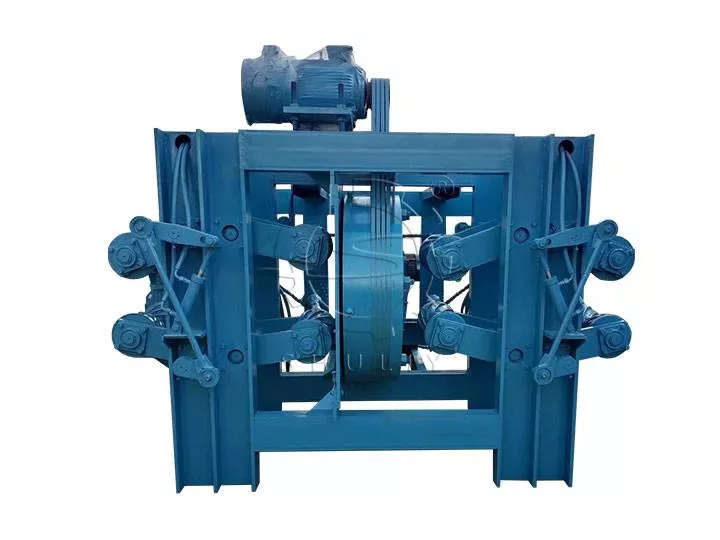

Drum wood chipper machine

Drum wood chipping machine is processing equipment used to cut fibrous and lumpy biomass raw materials such as wood, bamboo, straw, etc. into fine particles or thin slices. Its working principle is based on a cylindrical rotating drum with knife rollers and blades installed inside the drum, the raw material comes into contact with the blades inside the drum, and the wood is planed into the desired shape through the cutting of the blades.

Advantages of drum wood chips making machine

- Multi-directional cutting: due to the way the surface of the drum is cut, drum wood chippers are able to cut in multiple directions on the cylindrical surface, making the planing more wrap-around and helping to produce finer particles of shavings.

- Adaptable to different raw materials: drum wood chips making machine is suitable for different types of biomass raw materials, including wood, bamboo, straw, etc., with high raw material adaptability.

- Efficient processing: the rotary cutting method of the drum makes the processing more efficient and can quickly cut the raw materials into the required particles.

Main structure of the drum wood chipper

Blade: It is made of 9 complex silicon, which is strong and sturdy and not easy to be damaged.

Blade roller: Inside the machine, there are four knife rollers consisting of and supporting the blade, and the knife rollers are toothed. The material is hard and more resistant to wear.

Forced feeding device: This device is the location of the inlet, and its function is to press the wood to keep it from moving around, and to jam the wood to push it forward.

Drum wood chipping machine main parameters

The drum wood chipper has a large output and sells more than the disk chipper. The following two hot models are usually available.

Model: SL-218

- Knife Quantity: 2

- Feeding size: 300*680 mm

- Capacity: 10-15t/h

- Raw material dimension: ≤300 mm

- Wood chip size: 25 mm(Adjustable)

- Main power: 110 kw

- Weight: 8600 kg

Model: SL-216

- Knife Quantity: 2

- Feeding size: 230*500 mm

- Capacity: 5-8t/h

- Raw material dimension: ≤230 mm

- Wood chip size: 25 mm(Adjustable)

- Main power: 55 kw

- Weight: 5600 kg

Areas of wood chipper application

Wood chippers, also known as wood grinders or wood mills, are used in a wide range of industries due to their ability to process wood and other organic materials into smaller chips or pellets.

Some of the main application areas for wood chippers include forestry and logging, bioenergy production, pulp and paper industry, animal bedding and manure, furniture and woodworking.

The versatility of wood chippers, which convert wood and organic materials into useful products or resources, makes them an essential piece of equipment for several industries, contributing to sustainable practices, resource utilization and waste reduction.

Hot Product

Briquette charcoal dryer for honeycomb shisha coal production

Briquette charcoal dryer refers to the evaporation of…

Feed pellet mill machine for farming use

The feed pellet mill machine is a kind…

Wood chipper machine for sawdust-making plant

Wood chipper is a highly efficient wood processing…

Rotary drum dryer machine for sawdust powder drying plant

Rotary drum dryer machine is a common industrial…

Hydraulic shisha charcoal briquette machine for briquettes forming plant

Hydraulic shisha charcoal briquette machine is also a…

Wood crusher machine for making sawdust

The wood crusher machine plays a crucial role…

Wood debarker machine for wood chip production

The wood debarker is a machine that specializes…

Honeycomb coal machine for briquette forming production line

A coal briquette press machine is used to…

Wood shaving machine for animal bedding

The wood shaving machine is mechanical equipment used…