Wood debarker machine for wood chip production

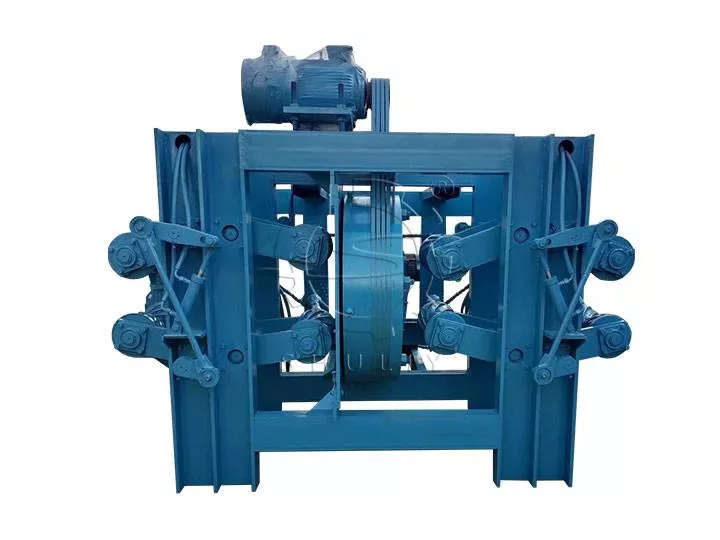

Wood peeling machine/Log debarking machine

Wood debarker machine for wood chip production

Wood peeling machine/Log debarking machine

Features at a Glance

The wood debarker is a machine that specializes in removing the skin from wood. It is usually used in the wood processing industry. The wood will be further processed after peeling. There are different types of wood debarker machines, vertical wood debarker machines, and horizontal wood debarker machines. Customers can choose the right form of the machine according to their needs.

Wood debarker machines made by Shuliy can efficiently strip the bark from the surface of the wood and increase the utilization and value of the wood. Our wood debarking machines are available in vertical and horizontal types. Meanwhile, they have different models to meet different wood debarking needs. The wood debarking machine can be used with a sawmill to make furniture. In the charcoal making machine line, it can subsequently be used in conjunction with a wood chipper and wood crusher.

Vertical wood debarker machine

The vertical wood debarker can process one raw wood at a time. The output is not big compared with the horizontal debarking machine. It can handle all kinds of branches, logs, trunks, etc., but the diameter is 5-35cm. The vertical wood skiving machine will change the pressure roller and cutter according to the thickness of the wood so that the skiving effect of the machine is good.

Operation of the vertical debarking machine

Start the wood skimmer and place the wood on the table. Place the rotating cutter or blade in contact with the surface of the wood.

The sharp edge of the cutter will then press against the bark layer on the surface of the wood and start cutting. Due to the rotation of the cutter, the bark layer will be gradually stripped and removed from the wood.

Advantages of vertical wood peeling machine

- High efficiency: Vertical wood skiving machine adopts rotating knives or blades for skiving operation, working speed is faster.

- Accurate peeling: The knives of the vertical wood peeling machine are close to the wood, which makes the wood more stable and the peeling process more precise and accurate.

- Space-saving: due to its vertical design, the vertical wood skiving machine occupies a relatively small space.

- Easy to operate: Simply place the raw material wood on the working table, start the electric drive system, and the peeling operation can begin.

Horizontal wood debarker machine

Horizontal wood skimmer can handle various shapes of wood. The diameter of the wood is usually under 30 centimeters. Horizontal wood debarker machines can process wood in batches. Therefore the efficiency is a bit higher. In order to save labor, picking and placing wood need to work with clamps and conveyor belts. According to our many years of experience, the horizontal wood debarking machine usually works together with the wood chipper to further process the equipment.

Working principle of horizontal wood flaking machine

The horizontal wood debarking machine utilizes the force generated by the rotor with debarking teeth to debark.

When the machine is working, the wood segments move in a circular motion, as well as irregularly jumping, in the slot plate of the bin week after week.

At the same time, the wood segments and teeth, wood segments and wood segments, wood segments, and the bin slot between the non-stop friction, and extrusion, the bark is quickly separated, to achieve the effect of peeling.

Strengths of using a horizontal debarker machine

- High efficiency: batch processing of various types and shapes of wood is more efficient.

- Wide range of applications: Horizontal wood skiving machine is suitable for processing different diameters and lengths of wood, which can meet the skiving needs of different sizes of wood.

- High stability: Due to its horizontal design, the working table is relatively stable and so is the operation of the machine.

- Reduced wood waste: Due to its high efficiency and stability, the horizontal wood peeling machine can reduce wood waste and increase wood utilization, thus reducing production costs.

- Safety: Horizontal wood skiving machines are usually equipped with various safety devices, such as guards, emergency stop buttons, etc., to ensure the safety of operators.

Finished products at a glance

The fresher the wood material, the better the skinning, and the cleaner and more beautiful the finished product will be.

Applications range of wood debarker machines

Wood debarker machines are specialized equipment used to remove the bark from logs and timber before further processing. These machines play a crucial role in preparing wood for various applications across different industries. The range of applications for wood debarker machines includes:

- Lumber and Timber Industry: One of the primary uses of wood debarker machines is in the lumber and timber industry. Debarked logs and timber are easier to process and have a smoother surface, which improves the efficiency of sawing, planing, and other milling operations.

- Pulp and Paper Industry: Debarking is an essential step in the production of wood pulp for papermaking. Bark removal ensures the quality and purity of the pulp and prevents contaminants from entering the paper production process.

- Wood Biomass and Bioenergy: In the production of wood biomass for energy generation, debarked wood is often preferred because it reduces the ash content and improves the combustion efficiency in biomass boilers and power plants.

- Wood Chip Production: Debarked logs are processed into wood chips, which are used in a variety of applications, including landscaping, animal bedding, and manufacturing engineered wood products.

- Furniture Manufacturing: Debarked timber is often used as raw material for furniture manufacturing. It provides a smoother surface and reduces the risk of damage to cutting tools during shaping and milling processes.

- Construction and Building Materials: Debarked logs can be processed into lumber and beams used in construction. Debarking helps ensure the structural integrity of the wood and reduces the risk of pests and decay.

Hot Product

Automatic saw mill machine for wood recycling plant

An automatic saw mill machine is a mechanical…

Horizontal carbonization furnace for lump charcoal making plant

Lump charcoal making machine is a kind of…

Comprehensive crusher in charcoal processing plant

The comprehensive crusher is a multi-functional processing equipment,…

Wood chipper machine for sawdust-making plant

Wood chipper is a highly efficient wood processing…

Rotary drum dryer machine for sawdust powder drying plant

Rotary drum dryer machine is a common industrial…

Wood debarker machine for wood chip production

The wood debarker is a machine that specializes…

Briquette charcoal dryer for honeycomb shisha coal production

Briquette charcoal dryer refers to the evaporation of…

Charcoal grinder machine for briquette molding plant

Charcoal grinder machine has the functions of crushing,…

Wood pallet press machine in pallets production making line

The wood pallet press machine is our featured…