Wood crusher machine for making sawdust

Wood crusher machine | Wood shredder machine

Wood crusher machine for making sawdust

Wood crusher machine | Wood shredder machine

Features at a Glance

The wood crusher machine is used to recycle waste wood and is ideal for crushing lumber, untreated wood, pallets, doors, slats, frames, and more. It is a specialized machine used for processing various types of wood. It can transform large chunks of raw materials into sawdust, which can be utilized in the production of biomass pellets, wood boards, and charcoal.

With this operation, it is possible to reduce the volume of wood waste. The large-capacity wood waste crusher operates very economically so that the wood is ready for subsequent processing, either as wood pellets or as fuel for cogeneration plants or waste treatment plants.

Wide applications of electric wood shredder

The wood crusher machine can effectively crush various materials such as raw logs, branches, waste wood boards, and discarded wooden construction materials. It can effectively process all types and sizes of wood and is ideal for crushing wood, untreated wood, pallets, doors, slats, frames, and more.

Structure of wood crusher machine

It generally contains a feeding port (which can be customized according to different materials), machine body (casing), crushing chamber, cutter disc, blades, screen (with adjustable size of the screen holes), discharge port, and other parts.

According to users’ requirements, the machine can also be equipped with a conveyor.

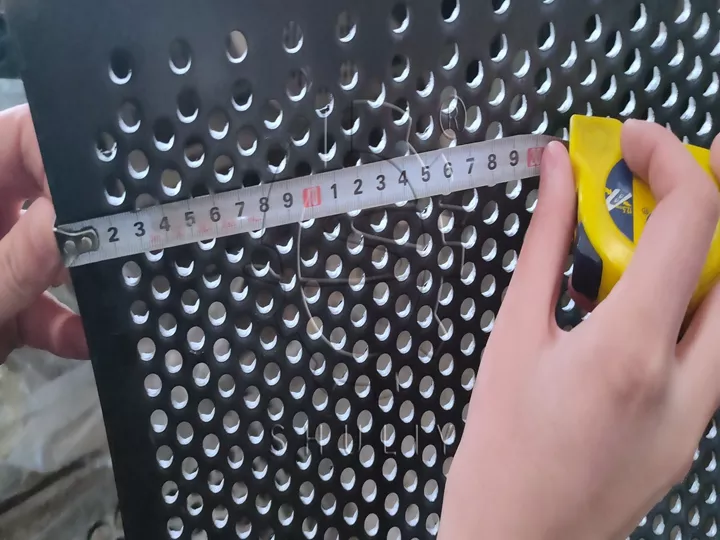

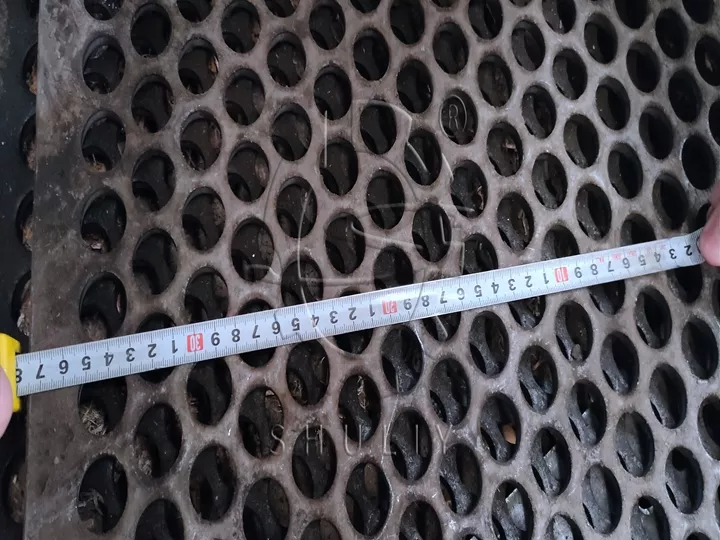

Sieves of wood crusher machine

Our wood crusher machine is equipped with sieves with different mesh sizes, allowing for the production of sawdust particles with varying fineness. Customers can choose the appropriate mesh size of the sieve based on their requirements.

Mobile wood crushing machine

We can add wheels to the bottom of the machine to facilitate the user to move to different scenarios.

Accessories of wood shredder machine

The main machine accessories include blades, cutter discs, hammer blades, and sieves. Hammer blades and cutter blades are consumable parts that customers can additionally purchase based on their needs.

How to operate this wood shredder machine

The electric wood shredder machine usually consists of one or more rotating blades or hammers, which tear, crush, and break the raw materials.

When the machine works, the motor drives the pulley to run at high speed. Then the cutter disc inside the machine casing is driven, pulling the blades on its upper side to run at a fast speed.

At this time, the wood materials are put into the feeding port, and then strongly shredded by the blades.

When the materials reach a certain size, they can pass through the screen and finally be discharged through the discharge port.

Supply:

- wood processing and recycling

Tools:

- wood crusher

Materials: waste wood

Demonstration and application of finished products

After being processed by the machine:

These sawdust particles can serve as the initial raw material processing program in charcoal briquette production lines. First, the wood is crushed into fine sawdust and then molded through the charcoal-making machine.

Power options for sawdust-making machine

The sawdust-making machine can be powered by electric motors, diesel engines, or diesel engine sets. Customers can choose the suitable power option according to their needs. We will also recommend the most appropriate power option based on customer requirements.

Advantages of wood crusher in sawdust making process

- Efficient processing capacity: The rotating blades or hammers of the wood crusher machine enable efficient wood crushing.

- Versatile applicability: The wood crusher machine is suitable for various types and sizes of wood and wood waste, displaying strong adaptability.

- Improved subsequent processing: The wood is processed into sawdust, making it easier for subsequent processing, such as producing biomass pellets, animal feed, paper, and wooden boards.

- Reduced transportation costs: After crushing, the wood’s volume is reduced, resulting in reduced transportation costs.

The wood crusher machine plays a crucial role in processing and recycling wood waste. It efficiently handles various types and sizes of wood, helping to reduce wood wastage. Due to its widespread applications and eco-friendly features, the sawdust making machine has gained widespread popularity in the wood processing and environmental industries.

Hot Product

Rotary shisha charcoal making machine for hookah briquettes

Rotary shisha charcoal making machine is a double-press…

Hookah charcoal packing machine for shisha briquette bagging plant

Hookah charcoal packing machine is a special equipment…

Automatic saw mill machine for wood recycling plant

An automatic saw mill machine is a mechanical…

Rotary drum dryer machine for sawdust powder drying plant

Rotary drum dryer machine is a common industrial…

Wood pallet press machine in pallets production making line

The wood pallet press machine is our featured…

Continuous carbonization furnace for rice husk charcoal making

Continuous charcoal carbonization furnace is an ideal equipment…

Briquette charcoal dryer for honeycomb shisha coal production

Briquette charcoal dryer refers to the evaporation of…

Wood crusher machine for making sawdust

The wood crusher machine plays a crucial role…

Shisha charcoal making machine for hookah briquette tablet production

The shisha charcoal making machine is also a…