Hookah charcoal packing machine for shisha briquette bagging plant

Shisha charcoal briquettes packaging machine/Pillow packing machine

Hookah charcoal packing machine for shisha briquette bagging plant

Shisha charcoal briquettes packaging machine/Pillow packing machine

Features at a Glance

The hookah charcoal packing machine is a special equipment for packaging water smoke charcoal. It is capable of automatically packaging water pipe charcoal lumps or pellets into bags or boxes according to predefined specifications and quantities.

This kind of packaging machine usually has the functions of automatic measuring, sealing, cutting, and discharging the packed products. Both hookah charcoal making machine and shisha charcoal packing machine are necessary equipment for the shisha charcoal production-making plant.

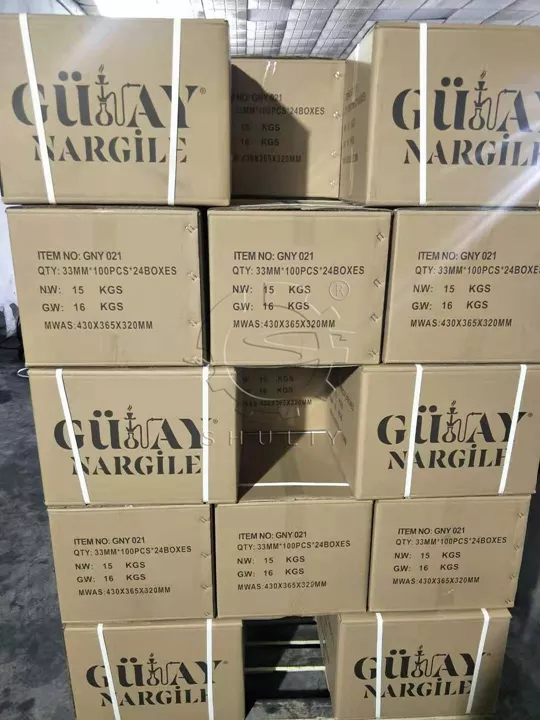

Packaging finished product display

In the charcoal production line sold by Shuliy Group, the hookah charcoal packing machine, as one of the supporting equipment, is mainly used to pack the shisha charcoal. The number of charcoal packed in each bag and the pattern of the bag can be customized and designed for customers.

Wide application of hookah charcoal packing machine

Hookah charcoal packing machine is a common packaging equipment, that is widely used in many fields, especially in the industries of food, medicine, cosmetics, and daily necessities. The following are some of the areas in which pillow packaging machines are commonly used:

- Food Industry: Pillow packing machine is widely used in the food industry for packaging of various food products, such as cookies, chocolates, candies, breads, noodles, powdered beverages, and so on.

- Pharmaceutical Industry: Pillow-type packaging machine is used in the packaging of pharmaceuticals, such as tablets, capsules, powder, ointment, etc., to ensure the sealing and hygiene of pharmaceuticals in the packaging process.

- Cosmetic industry: A Hookah charcoal packing machine can be used for the packaging of cosmetic products, such as face masks, cosmetic samples, perfume, skin care products, etc., to ensure the appearance and quality of the products.

- Industrial products: Shisha charcoal packing machines can also be used for the packaging of industrial products, such as parts, accessories, electronic products, and so on.

- Agricultural products: This machine can also be applied to the packaging of agricultural products, such as dried fruits, nuts, tea, and so on.

The hookah charcoal packing machine forms compact packages by placing the products into plastic film bags, which are then sealed and cut. It is suitable for a wide range of products of different shapes and sizes, improving packaging efficiency and consistency of package appearance.

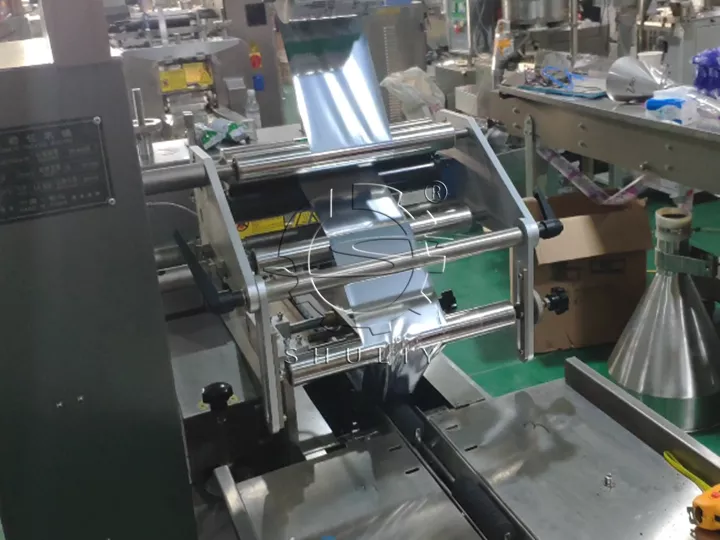

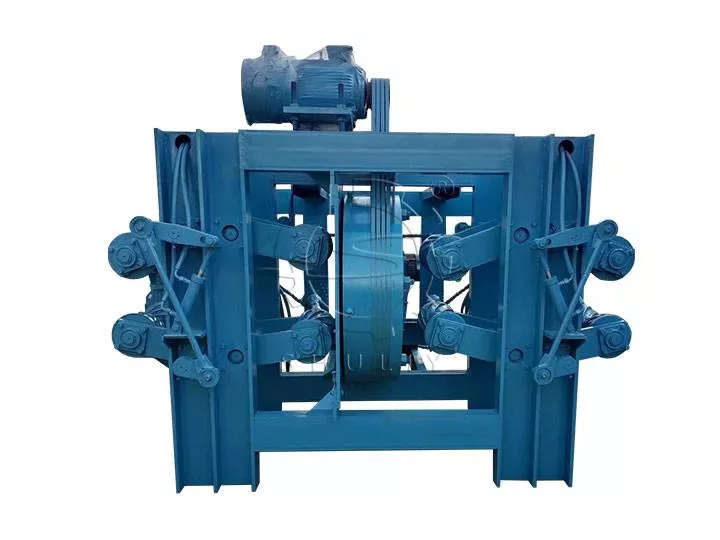

Structure of shisha charcoal packaging machine

The hookah charcoal packaging machine mainly includes a feeding system, measuring system, bag or box supply system, sealing system, cutting system, control system, conveying system, shell, and stand.

Working video of hookah charcoal packing machine

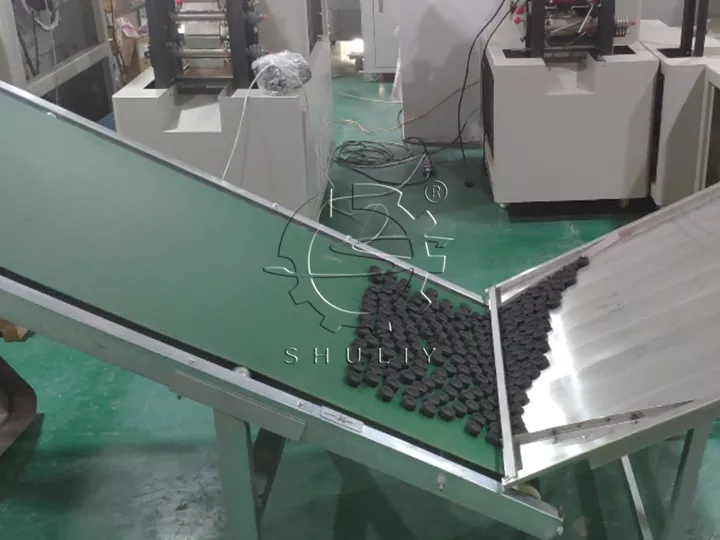

Shisha charcoal packing machine workflow

The entire process is automated and precisely controlled by mechanical drives, sensors, and control systems to ensure that each product is correctly packed and closed.

- Feeding and Positioning: First, the product is transported to the working area of the packaging machine through the feeding device.

- Film Unfolding: The packaging machine uses a continuous roll of packaging film which will be used to wrap the product.

- Forming the bag: In this step, the film is folded and closed on one side to form a bag. The shape of the bag can be rectangular or oblong, and looks like a “pillow”, hence the name “pillow packaging.

- Filling the product: Next, the product is precisely placed into the formed bag. Typically, the product enters the bag from above, and the bag is continuously moved by a conveyor belt or film.

- Closing and Cutting: Once the product has been placed into the bag, the other side of the bag will be closed while the space between the bags is sealed into individual packages. Next, the bags will be cut as needed to make each bag an individual, sealed package.

- Outfeed: Finally, the completed bags are removed from the outfeed end of the packaging machine, usually via a conveyor or other device for collection or further transportation.

Technical information about the charcoal bagging machine

The technical parameters of pillow packaging machines may vary depending on the model, manufacturer, and application requirements. Below are the technical parameters of the THB-280 model for reference:

- Model: THB-280

- Packaging film width: 100-280mm

- Bag length: 80-300mm

- Product Height: 5-60mm (above 60mm customized according to customer’s requirements)

- Membrane roll diameter: ≤320mm

- Packaging speed: 120 bags/min

- Power supply: 220V 50HZ 2.5kw

- Dimension: (L)4000×(W)900×(H)1500mm

- Weight: 500kg

Features of hookah charcoal packing machine

- Double inverter control, bag length is set and cut, one step, save time and film.

- Human-machine interface, convenient and quick parameter setting.

- Temperature-independent PID control is better suited to a variety of packaging materials.

- The simple transmission system, more reliable work, and maintenance are more convenient.

- Fault self-diagnosis function, fault display at a glance.

- High-sensitivity photoelectric eye color-coded tracking, digital input sealing, and cutting position, so that the sealing and cutting position is more accurate.

Why use a pillow packing machine to pack hookah charcoal

- Enhance the product image: The pillow packing machine can pack hookah charcoal blocks or pellets neatly and beautifully, which makes the product appearance more attractive.

- Saving packaging materials: The Hookah charcoal packing machine adopts reasonable packaging methods and sizes, which can maximize the saving of packaging materials and reduce packaging costs.

- Ensure hygiene and safety: The shisha charcoal packing machine is made of stainless steel, which is easy to clean and sterilize, and helps to guarantee the hygiene and safety of hookah charcoal.

- Increase the scale of production: The use of hookah charcoal packing machines can realize mass production and large-scale packaging to meet market demand and expand the scale of business.

Hot Product

Rotary drum dryer machine for sawdust powder drying plant

Rotary drum dryer machine is a common industrial…

Shisha charcoal making machine for hookah briquette tablet production

The shisha charcoal making machine is also a…

Wood debarker machine for wood chip production

The wood debarker is a machine that specializes…

Charcoal Ball Press Machine For BBQ Industry

Charcoal ball press machine is efficient and convenient…

Pallet block machine for wooden packaging production plant

The wood pallet block machine is an automated…

Sawdust briquette machine for biomass charcoal processing line

Biomass charcoal making machine can extrude and shape…

Hookah charcoal packing machine for shisha briquette bagging plant

Hookah charcoal packing machine is a special equipment…

Hydraulic shisha charcoal briquette machine for briquettes forming plant

Hydraulic shisha charcoal briquette machine is also a…

Wood shaving machine for animal bedding

The wood shaving machine is mechanical equipment used…