Rotary shisha charcoal making machine for hookah briquettes

Continuous shisha charcoal machine/Rotary hookah charcoal machine

Rotary shisha charcoal making machine for hookah briquettes

Continuous shisha charcoal machine/Rotary hookah charcoal machine

Features at a Glance

Rotary shisha charcoal making machine is a double-press type automatic rotary, continuous tablet press, mainly used for pressing powdered raw materials into tablets. The machine can make water-smoked charcoal besides.

It is mainly used for tablet production in the pharmaceutical industry, and is also applicable to chemical, food, electronic, and other industrial sectors.

Overview of rotary shisha charcoal making machine

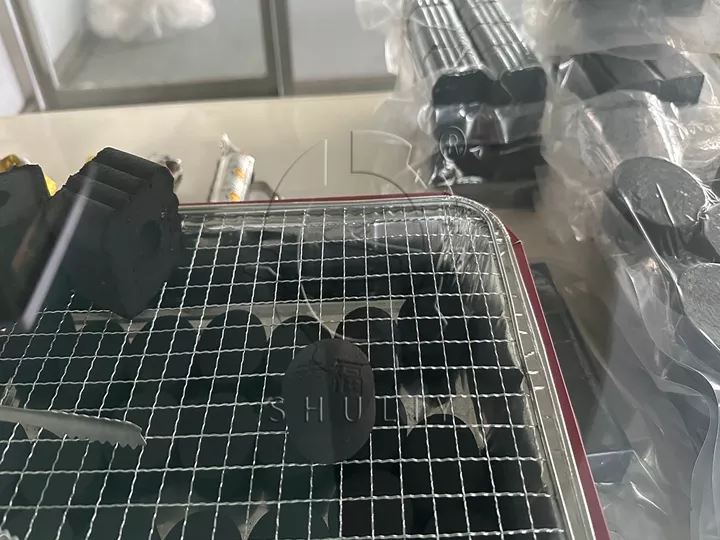

Our rotary shisha charcoal-making machine specializes in pressing coconut shell charcoal powder, fruit wood charcoal powder, bamboo charcoal powder, and charcoal powder, which is crushed by the hammer mill crusher, to make various shapes of hookah charcoal tablets.

Besides pressing round tablets, we can also produce shaped tablets, special tablets, square tablets, and so on. We can customize it according to your requirements. Finished round pieces are commonly 33mm and 34mm in diameter; finished square pieces usually measure 20*20*20mm and 25*25*25mm.

When the rotary shisha charcoal making machine is running, the machine noise is small, but the pressure is big, and it is equipped with an over-pressure stop function to make sure the machine is not damaged.

Main applications of the finished product

The rotary shisha charcoal making machine is mainly used to prepare hookah charcoal, which is a fuel block used in hookah pipes. The hookah charcoal has specific combustion properties and a unique flavor and is used to produce hookah smoke, which is commonly used for hookah smoking.

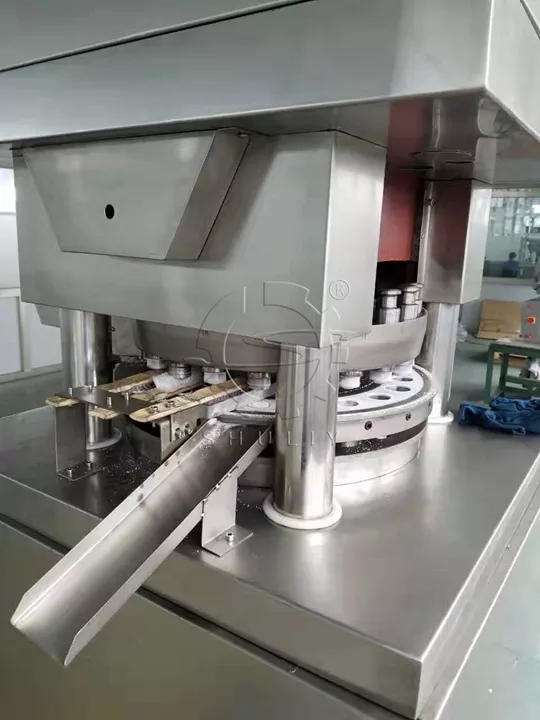

Rrotary shisha charcoal making machine main structure

The rotary shisha charcoal-making machine mainly consists of the frame, the turntable, the tablet press mold, the power, the control system, the discharge system, etc. This machine is mainly used for the production of tablets and other tablets. Among them, the turntable and mold are the core parts of the rotary tablet press and the main working area for manufacturing charcoal briquettes.

Rotary shisha charcoal making machine working video

Workflow of shisha charcoal making process

Making hookah charcoal often requires several processes: raw material crushing→mixing with binder→molding→drying→packaging. The corresponding machines are as follows.

Raw Material Preparation

Firstly, raw materials for the preparation of hookah charcoal need to be prepared, which are usually wood chips, bamboo chips, etc. containing fibers. These raw materials will be crushed and broken to less than 3mm through a hammer mill for the subsequent molding process.

Mixing

The raw materials will be mixed with an appropriate amount of binder in order to maintain the shape and provide a certain bonding force during the preparation of the hookah charcoal. The binder may be vegetable gum, starch, etc. This operation is carried out in the charcoal powder grinding machine.

Feeding and Molding

Under the action of the rotary flaking charcoal machine, the raw materials are compressed into small pieces of a certain shape, which will be squeezed out through the holes in the rotating disk. This process is actually a kind of extrusion and molding process.

Drying

After molding, the water-smoked charcoal briquettes need to be dried in the batch charcoal drying machine (60-80℃, 8h/batch) to remove the moisture in them, increase the calorific value, and improve their stability.

Packaging and Storage

The dried hookah charcoal briquettes can be packaged through a hookah charcoal packing machine for transportation and sale. It can also be stored in a dry and ventilated place to ensure that its quality is not damaged.

Rotary hookah charcoal machine technical information

The technical parameters of rotary shisha charcoal making machines may vary according to different models, manufacturers, and design requirements. Below are some common possible technical parameters of this machine:

| Model | SL-ZP-17B |

| Punch quantity(sets) | 17 |

| Max. tablet pressure(kn) | 120 |

| Max. tablet diameter(mm) | 36 |

| Max. filling depth(mm) | 18-30 |

| Max. tablet thickness(mm) | 8-15 |

| Turret rotation speed(r/min) | 10-25 |

| Upper and lower punch diameters(mm) | 40 |

| Upper punch length(mm) | 175 |

| Lower punch length(mm) | 180 |

| Middle mold diameter(mm) | 52 |

| Max. output(pcs/h) | 25500 |

| Motor power(kw) | 7.5 |

| Overall size(mm) | 900x800x1640 |

| Machine weight(kg) | 1500 |

Please note that different models and manufacturers of rotary shisha charcoal making machines may have different technical parameters. When choosing the right machine, you need to consider the above technical parameters and other possible influencing factors according to your own needs, production scale, and actual situation.

Main features of rotary shisha charcoal making machine

- The rotary tablet press machine is advanced in design, the peripheral cover is fully closed and made of stainless steel, which is in line with GMP requirements. The internal table top is specially treated to maintain luster and prevent cross-contamination.

- We equip the machine with transparent glass doors and windows to facilitate clear observation of the tablet pressing status. All doors and windows can be opened for easy internal cleaning and maintenance.

- The rotary charcoal press machine is equipped with an overload protection device, and automatic shutdown when the pressure is overloaded, to protect the safe operation of the equipment.

- PLC and touch screen control, are easy to operate, the user can intuitively display and set all kinds of parameters.

- The electrical control box is separated from the host to avoid dust contamination of electrical components, and the longer service life of the machine.

- The buyer can choose an optional forced feeding device, which can improve production efficiency.

Rotary shisha charcoal making machine sold to Morocco

Last month Morocco customer purchased a rotary shisha charcoal making machine from us. The customer’s demand was clear and directly sent us an inquiry for the hookah charcoal tablet press. At first, we sent different types of charcoal briquette making machines to the customer, finally, the customer chose the rotary tablet press type.

Then we immediately provide PI to the customer and send more videos and pictures of the machine. The customer was satisfied with our charcoal briquette press machine and then paid the deposit.

Precautions for the use of charcoal briquette press machine

- People must repeatedly check the quality of the punching mold before use to make sure that there are no missing edges, cracks, deformations, and incomplete tightening and loosening.

- Managers should be familiar with the technical performance of the charcoal briquette press machine, the internal structure, and the principle of using the control mechanism. They should not leave the working place during the operation to prevent failure and damage to the machine parts.

- If there is a screaming or strange sound in use, stop the machine immediately to check and eliminate the fault, do not use it reluctantly.

- Rotary tablet press on the shield, safety cover, and other devices shall not be removed, be sure to install when in use.

- Use dry raw materials to avoid powder sticking to the punch surface.

- If the tablets jump or stagnate during the operation, the staff must not take them by hand to avoid the accident of hurting hands.

Hot Product

Charcoal briquette mesh belt dryer for continuous drying plant

Charcoal briquette mesh belt dryer is a continuous…

Wood chipper machine for sawdust-making plant

Wood chipper is a highly efficient wood processing…

Continuous carbonization furnace for rice husk charcoal making

Continuous charcoal carbonization furnace is an ideal equipment…

Honeycomb coal machine for briquette forming production line

A coal briquette press machine is used to…

Hydraulic shisha charcoal briquette machine for briquettes forming plant

Hydraulic shisha charcoal briquette machine is also a…

Shisha charcoal making machine for hookah briquette tablet production

The shisha charcoal making machine is also a…

Charcoal briquette machine for fuel production line

Coal press machine is one of the coal…

Rotary drum dryer machine for sawdust powder drying plant

Rotary drum dryer machine is a common industrial…

Comprehensive crusher in charcoal processing plant

The comprehensive crusher is a multi-functional processing equipment,…